Install Steam

login

|

language

简体中文 (Simplified Chinese)

繁體中文 (Traditional Chinese)

日本語 (Japanese)

한국어 (Korean)

ไทย (Thai)

Български (Bulgarian)

Čeština (Czech)

Dansk (Danish)

Deutsch (German)

Español - España (Spanish - Spain)

Español - Latinoamérica (Spanish - Latin America)

Ελληνικά (Greek)

Français (French)

Italiano (Italian)

Bahasa Indonesia (Indonesian)

Magyar (Hungarian)

Nederlands (Dutch)

Norsk (Norwegian)

Polski (Polish)

Português (Portuguese - Portugal)

Português - Brasil (Portuguese - Brazil)

Română (Romanian)

Русский (Russian)

Suomi (Finnish)

Svenska (Swedish)

Türkçe (Turkish)

Tiếng Việt (Vietnamese)

Українська (Ukrainian)

Report a translation problem

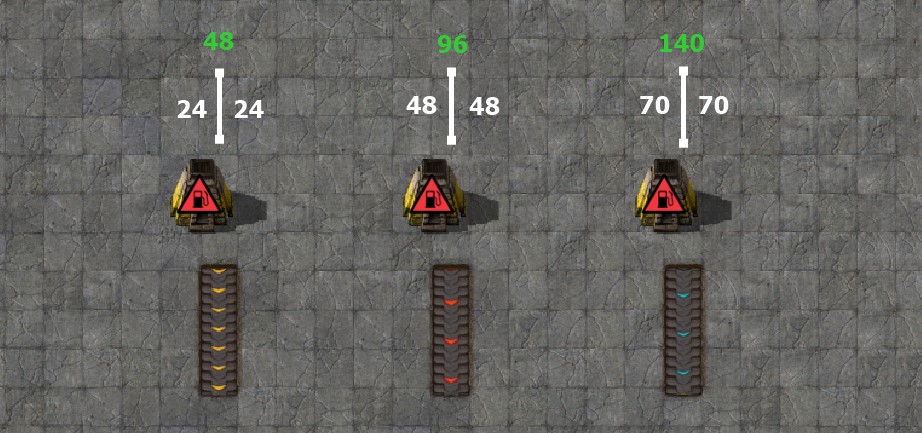

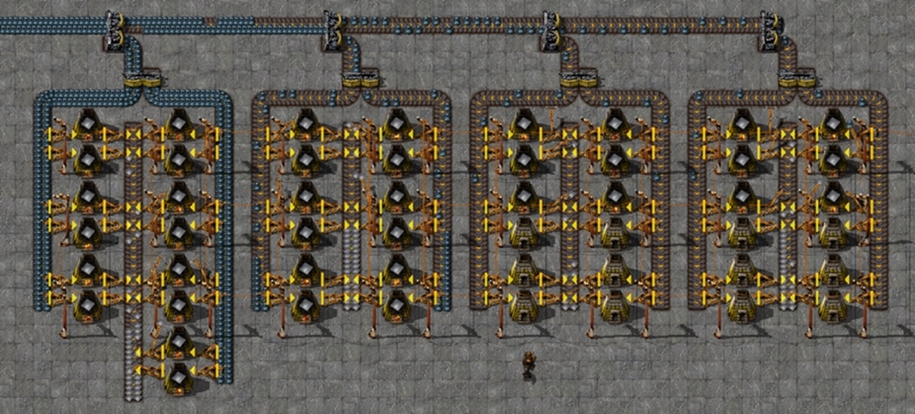

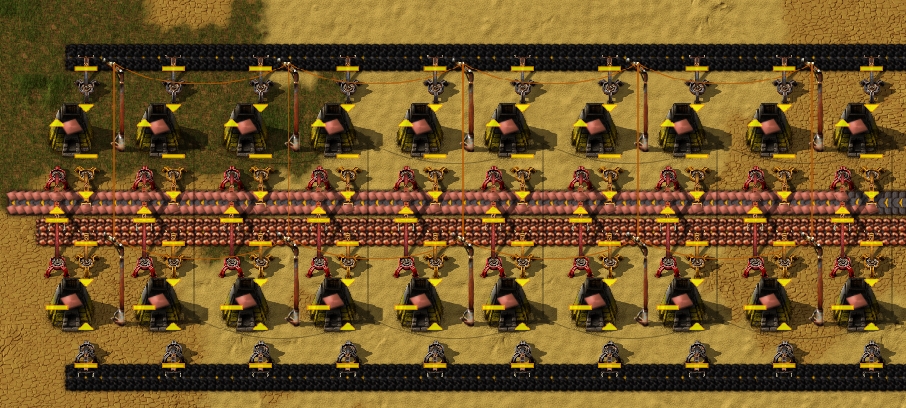

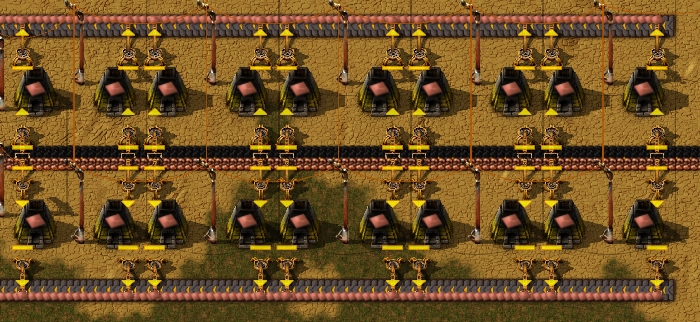

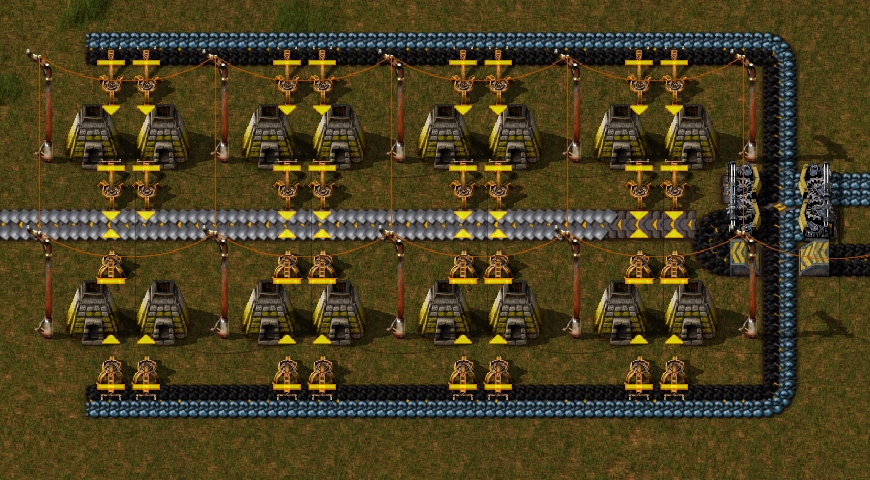

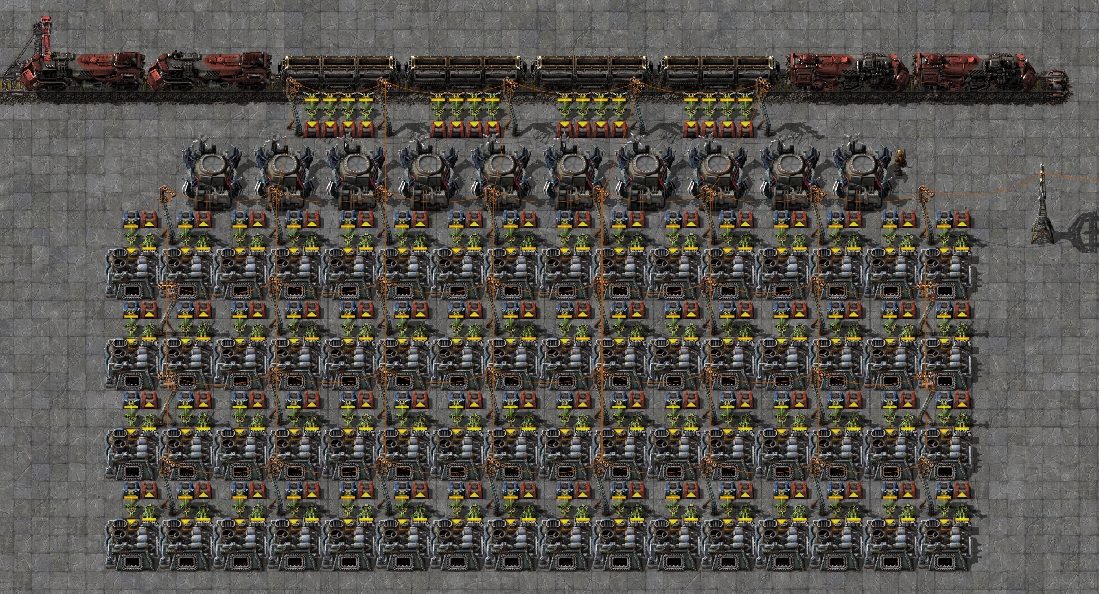

Did I miss something because I don't see how the second design is going to use less inserters. You still need 1 inserter for coal/ore input and 1 for plate output.

Otherwise the guide is really good, thanks for all the effort.